A company has won a three year fight with Fenland District Council to keep its business operating from Kingsland Farm, March Road, Coates near Whittlesey. Stair Formwork Ltd is an expanding independent manufacturer of lightweight modular stair formwork.

The end product is used by builders, architects, structural engineers, property developers and civil engineers across the UK.

The company opened discussions with the council in 2021 for a retrospective change of use of existing warehouses and yard from a storage and distribution depot to industrial use.

In late 2022 they submitted the application and a year later Fenland Council refused it, claiming the company had filed ‘insufficient information’ to deal with noise and the impact on neighbouring properties.

The council also claimed insufficient detail had been provided to tackle surface water management and drainage.

The application attracted only two objections – local councillor Alex Miscandlon and his wife who lived nearby, and Whittlesey town council.

Cllr Miscandlon’s personal objection also formed the basis of the town council objections in which he claimed there were “inaccuracies” in the Stair Formwork application in respect of flood risk and drainage.

He (and the town council) also claimed working times suggested by the company “are not in line with those agreed with the Government for the health and well being of the neighbouring properties”.

The letter from the Miscandlons also mentioned “constant noise from fork trucks, sounding of horns also dragging steel parts across the concrete floors and hard standing. This was also heard by FDC environmental health officers”.

He added: “This site has been subject to two Government Ombudsman inquiries. The first was inclusive and the second found that FDC failed the local residents in view of complaints not being dealt with in an appropriate manner, thus failing to monitor an out of control site”.

Whittlesey town council planning committee took just 4 minutes to recommend refusal after Cllr Miscandlon addressed them in a personal capacity.

Planning records show the application was refused under delegated powers by Fenland Council after planning committee chair Cllr David Connor agreed.

“Have read the planning officers excellent report, I strongly agree with the planning officers decision to refuse the application,” he wrote.

“Reasons being – no up to date noise assessment and in my view no proper drainage strategy. The working hours proposed would in my view be determinantal to the health and wellbeing of local residents.”

But last week came news that Stair Form had successfully contested the Fenland Council refusal and are free to continue their business operations.

G Pannell, a planning inspectorate, in his ruling, approved the change of use with some conditions.

These include acceptance of noise impact measures proposed by the company and no waste associated materials to be disposed of into a skip prior to 8am on any working day.

He also said there must be no outside fabrication working under normal operating conditions.

Other conditions include restricting operating hours to 7am to 4pm Mondays to Thursday, 7am to 1pm on Fridays and 8am to noon on Saturdays.

“The council’s appeal statement confirms that evidence submitted at appeal has addressed its concerns and on this basis the council is no longer pursuing any of its reasons for refusal as outlined in its decision notice,” said Mr Pannell.

Mr Pannell explained that the company manufactures lightweight modular stair formwork for commercial concrete stairs; a process that involves the movement, cutting, forming, welding, and painting of steel.

“The handling and use of steel is inherently prone to noise generation and the process of manufacture inevitably generates a certain amount of impulsive noise events,” he said.

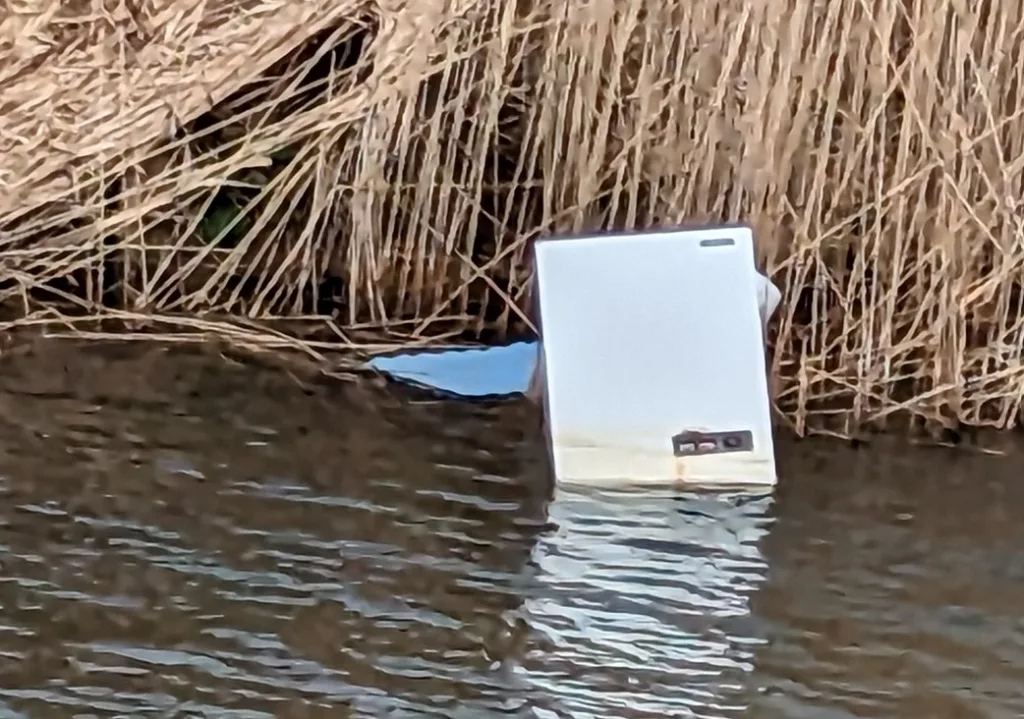

“All work on the products is carried out inside two workshops, steel framed and profiled-steel clad buildings. The buildings are not lined internally but the paint workshop has been spray-foamed for thermal insulation.

“The finished products are stored outside the buildings in preparation for delivery, which takes place daily with early morning loading and departure.”

He described the location of the business as a small commercial park previously used for farming operations, predominantly fruit packing and storage/distribution.

“The closest residential receptor is 4 Wisbech Road, which is approximately 60 – 100m from the appeal site,” he said.

“The garden of the property borders the commercial site.”

He said monitoring of noise took place in the rear garden of 4 Wisbech Road and “identified that the noise environment at the measurement location was a combination of passing traffic on the A605 and activity from the commercial park.

“It also identified that there was a steady low background hum from the newly installed extract fans in the paint-shop, and there were a number of impulsive noise events associated with operations from existing commercial sources on the industrial estate, primarily from the appellant’s site.

“These included metal ‘clanging’ and movement of stock by forklift. However, traffic is the dominant contributor to the overall noise level measured”.

The inspector said the original application did not include any information on the predicted noise levels when installation had been completed and therefore a further noise impact assessment was required.

Additional information now submitted “has addressed the concerns previously raised by the council and they no longer wish to pursue this reason for refusal.

“As such there is nothing to dispute the appellants findings that the mitigation measures have resulted in a reduction in the overall noise levels and is willing to accept a condition to ensure that they are implemented and maintained”.